JT Sprockets

JT sprockets are made using only the best available materials. Aviation-grade 7075-T6 aluminium alloy for lightweight competition sprockets, SCM420 chromoly steel alloy for front sprockets, and we are the only sprocket manufacturer using the ultra-durable high carbon C49 steel for rear sprockets.

Production

The JT Sprockets factory is the largest and most advanced in the world. It is fully equipped with high accuracy machinery, including the latest generation of CNC computer design and computer controlled metal cutting equipment.

The essence of a high quality sprocket is in the high precision of manufacturing and the inherent quality of the material. Through accurate machining, JT ensures maximum durability and performance.

JT Sprockets are manufactured the right way – by hobbing, machining and drilling. This is the only proven way to achieve the closest of tolerances and the most accurate teeth profiles.

Heat treated and hand finished to perfection, all JT sprockets meet or exceed the highest possible quality standards set for the motorcycle industry.

Quality Control

Every sprocket goes through up to 25 production stages and 10 individual quality control checks before it is ready to leave the factory and the production facility has achieved the highest European quality standards.

JT Rear Sprocket, Standard Steel for Yamaha TZR 250 & YPVS350 R846

JT Steel Sprockets are manufactured using only the finest grade of C49 high carbon steel for the rea..

£17.41

TZR250 JT Front Sprocket Standard Steel F565 Standard Size 14T, 13t - 18T available as options

JT Steel Sprockets are manufactured using only the finest grade of C49 high carbon steel for the rea..

£7.98

TZR250 JT Front Sprocket Steel, Lightweight, Self Cleaning F565SC Standard Size 14t, 12T, 13t available as options

MX-series steel front sprockets are manufactured to exacting tolerances and designed with special se..

£8.40

BMW S1000R JT Front Sprocket Rubber Cushioned Steel F404RB Standard Size 17t

Rubber cushioned sprockets have been widely used by the major Japanese and European motorcycle manuf..

£14.05

TZR250 JT Front Sprocket Rubber Cushioned Steel F565RB Standard Size 14T, 15T, 16t available as options

Rubber cushioned sprockets have been widely used by the major Japanese motorcycle manufacturers sinc..

£8.90

YPVS350 JT Front Sprocket Standard Steel F569 Standard Size 17T, 10t - 18T available as options

JT Steel Sprockets are manufactured using only the finest grade of C49 high carbon steel for the rea..

£7.90

Kawasaki KDX200 Front Sprocket 520Pitch, 14t

Front sprocket for Kawasaki KDX200. Standard size 14t, options available from 10tooth - 18toot..

£8.61

Yamaha RD250 LC and RD350 LC Front Sprocket 530Pitch, 14-18t

Front sprocket for Yamaha RD250 and RD 350 LC Models. Standard size 16t, options available fro..

£8.61

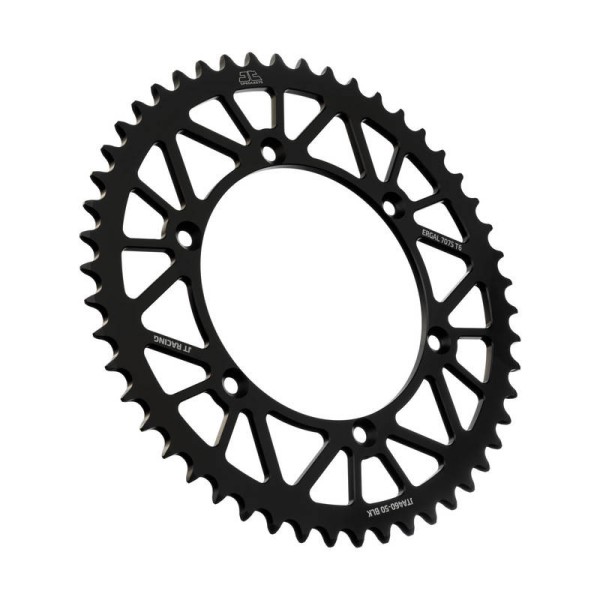

JT Alloy Rear Sprocket to fit Kawasaki KDX200, 520 Pitch, 48 Tooth

Precision CNC machined to JT’s uncompromising standards from certified 7075-T6 Ergal aviation grad..

£31.66

JT SPROCKET FRONT JTF1370.16

JT SPROCKET FRONT JTF1370.16 for Fireblade 1996-9 (RR-T,V,W,X)..

£12.57

JT SPROCKET FRONT JTF333.16

JT SPROCKET FRONT JTF333.16 for Fireblade 1992-5 (RR-N,P,R,S), 2000-2003(Y,1,2,3)..

£12.12

JT SPROCKET REAR JTR1304.42 (0304.42)zbk

JT SPROCKET REAR JTR1304.42 (0304.42)zbk for Fireblade 1996-9 (RR-T,V,W,X)..

£20.75

LITHIUM ION BATTERY / REPLACES YTX9-BS HJTX9-FP-I

LITHIUM ION BATTERY / REPLACES YTX9-BS HJTX9-FP-I for Fireblade 1992-9 (RR-N,P,R,S,T,V,W,X)..

£67.19