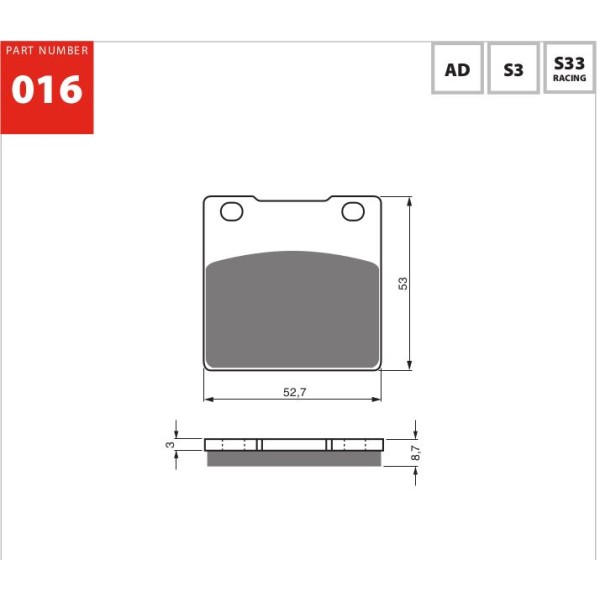

Sintered brake pads one pair (two packs required for twin disc setup). Available compounds are shown in the image.

GOLDfren only manufactures sintered brake pads. Their sintered brake pads are composed of metal-ceramic and ceramic-carbon friction materials. These materials allow for less friction material dust and a much quieter braking experience as much of the sound generated is at a frequency beyond the human hearing range.

GOLDfren sintered brake pads are manufactured with a modern method of powder metallurgy, which proven manufacturing technology along with essential quality control systems ensures that the finished product consistently achieves the required material properties. Their aim is to provide the highest levels of thermal and mechanical endurance,coupled with high coefficient of friction for the greatest braking effect and longevity even under the heaviest braking conditions.

The use of non-aggressive materials on GOLDfren brake pads ensures that high friction levels are achieved while minimising rotor wear levels. The materials used are environmentally friendly, and DO NOT contain any of the following harmful materials: lead, asbestos, fibreglass or formaldehydes.

There are eight choices of compound in the GOLDfren range, allowing riders to select the most appropriate braking characteristics for their riding style. Details can be found in the product pages.

Standard Unit Price: £16.25

GOLDfren Motorcycle Brake Pad 700016

- Brand: GOLDfren Motorcycle Brake Parts, Friction Materials, Pads

- Product Code: 700016

- Availability: 2-3 Days

-

£16.25